© Website by Tooling Research Inc.

It is easy for the designer to get carried away with details of a component in the design process.

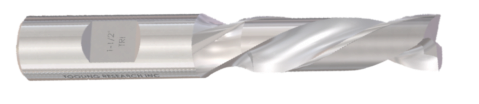

One of the things a machinist often sees is the addition of very small chamfers on parts where the engineer or designer is attempting to show a

requirement for edge breaks, sometimes referred to as eased edges.

Simply put this means no sharp edges and in the machine shop world these are very often hand filed, sanded, or otherwise deburred.

In this case, it is better if the designer omits the feature from the part entirely and instead provides a notation on the drawing itself detailing this

requirement. This is because most machine shops use some form of CAM (computer aided Manufacturing) program to create your parts and very

often picking the correct face or edges can be difficult when very small chamfer or fillet features are included on the model. Often times the program

will use a face feature to create a perimeter which means that the part could be machined right to that feature size making it smaller by the amount

of the chamfer or fillet callout.

In short the designer should be considering these things.

* Can the feature in this model be machined using conventional methods and tooling?

* Do the tools required to make this part or feature exist, or are they custom?

* Are there features on this part that make it easy to hold during the machining process, or will special fixturing or anchor material be needed?

* Can I eliminate unnecessary fillets chamfers etc in order to make this part less expensive, or do I need to have them?

* Have I added unnecessary draft angles?

* Have I avoided designing internal reverse angles or drafts in blind pockets?

* Did I remember to avoid sharp inside corners where ever possible?

This article is not meant to be a primer in the art of machining as much as it is meant to point out just a few of the problems faced by the machinist.

Hopefully this will provide some insight into ways to make your designs more economical to manufacture.

Whenever you have a question regarding the feasibility of your design from a machining standpoint, call on your local machine shop. Most will be

happy to make suggestions and give advice on practical machining matters. Ultimately you, the engineer or designer, will be the one to determine

what your final part will look like. Very often a few simple tweaks of a design can save thousands of dollars for you and your company.

Milton Florest

President

Tooling Research Inc.

81 Diamond St.

Walpole, MA 02081

508 668 1950

Website www.tooling-research.com

Think like a machinist when creating solid models page 7

PAGE 7

© Website by Tooling Research Inc.

Think like a machinist when creating solid models page 7

PAGE 7

It is easy for the designer to get carried away with

details of a component in the design process.

One of the things a machinist often sees is the addition of

very small chamfers on parts where the engineer or

designer is attempting to show a

requirement for edge breaks, sometimes referred to as

eased edges.

Simply put this means no sharp edges and in the machine

shop world these are very often hand filed, sanded, or

otherwise deburred.

In this case, it is better if the designer omits the feature

from the part entirely and instead provides a notation on

the drawing itself detailing this

requirement. This is because most machine shops use

some form of CAM (computer aided Manufacturing)

program to create your parts and very

often picking the correct face or edges can be difficult

when very small chamfer or fillet features are included on

the model. Often times the program

will use a face feature to create a perimeter which means

that the part could be machined right to that feature size

making it smaller by the amount

of the chamfer or fillet callout.

In short the designer should be considering these

things.

* Can the feature in this model be machined using

conventional methods and tooling?

* Do the tools required to make this part or feature exist,

or are they custom?

* Are there features on this part that make it easy to hold

during the machining process, or will special fixturing or

anchor material be needed?

* Can I eliminate unnecessary fillets chamfers etc in order

to make this part less expensive, or do I need to have

them?

* Have I added unnecessary draft angles?

* Have I avoided designing internal reverse angles or drafts

in blind pockets?

* Did I remember to avoid sharp inside corners where ever

possible?

This article is not meant to be a primer in the art of

machining as much as it is meant to point out just a few of

the problems faced by the machinist.

Hopefully this will provide some insight into ways to make

your designs more economical to manufacture.

Whenever you have a question regarding the feasibility of

your design from a machining standpoint, call on your local

machine shop. Most will be

happy to make suggestions and give advice on practical

machining matters. Ultimately you, the engineer or

designer, will be the one to determine

what your final part will look like. Very often a few simple

tweaks of a design can save thousands of dollars for you

and your company.

Milton Florest

President

Tooling Research Inc.

81 Diamond St.

Walpole, MA 02081

508 668 1950

Website www.tooling-research.com